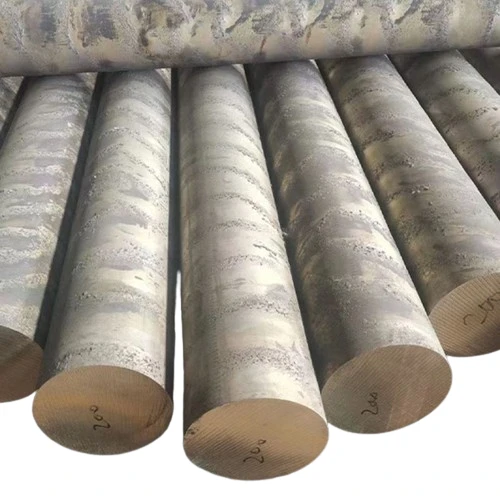

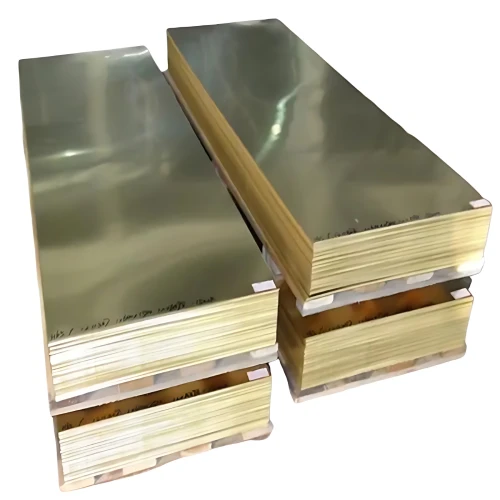

C95400: The All-Purpose Aluminum Bronze for Strength, Castability, and Corrosion Resistance

C95400. also known as C954 or 9C aluminum bronze, is a popular copper alloy belonging to the aluminum bronze

family. It's prized for its well-rounded properties, offering a good balance of strength, castability,

and corrosion resistance. Here's a closer look:

Table: Key Properties of C95400

| Property |

Description |

| Chemical Composition |

- Primarily Copper (Cu): Balance <br> - Aluminum (Al): Nominal 4% <br> - Iron (Fe):

Up to 4% with the option of adding up to 1.5% Nickel (Ni)

|

| Mechanical Properties |

- Good tensile and yield strength <br> - Good castability for intricate shapes <br>

- Fair machinability <br> - Moderate corrosion resistance

|

| Common Brands (By Country) |

- Europe: CuAl4Fe4 [Europe] <br> - US: Aluminum Bronze, C954 |

Important Note: Brand names might vary depending on the supplier. Nickel content can vary,

so always check the specific datasheet.

Common Questions and Answers:

What are the typical applications of C95400?

C95400's versatility makes it suitable for various applications:

Valves and fittings: While regulations might limit its use in some areas, C95400 has been

traditionally used for valves and fittings due to its castability and strength.

Gears and bushings: It can be used for gears and bushings in applications with moderate

loads.

Marine hardware: C95400 offers moderate corrosion resistance for some marine hardware

applications.

Architectural elements: Due to its castability and aesthetics, C95400 can be used for

decorative elements like railings and plaques.

How does C95400 compare to other copper alloys?

C95400 offers a good balance:

Versatility: Compared to some specialized copper alloys, C95400 offers a balance of

properties suitable for various applications.

Castability: It offers good castability for intricate shapes, making it suitable for

complex components.

Are there alternatives to C95400?

Depending on the specific needs, consider these alternatives:

High-strength aluminum bronzes: Offer superior strength but might be more expensive and

have lower castability.

Leaded brasses (e.g., C85700): Can provide good castability and machinability at a lower

cost, but with lower strength and environmental concerns due to lead.

Silicon bronzes (e.g., C65620): Offer good castability, corrosion resistance, and fair

strength, but might lack the same machinability.

Important Note: Always consult with a material engineer or supplier to identify the most

suitable copper alloy for your specific application considering factors like strength, castability,

corrosion resistance, machinability, lead content (regulations), and cost.