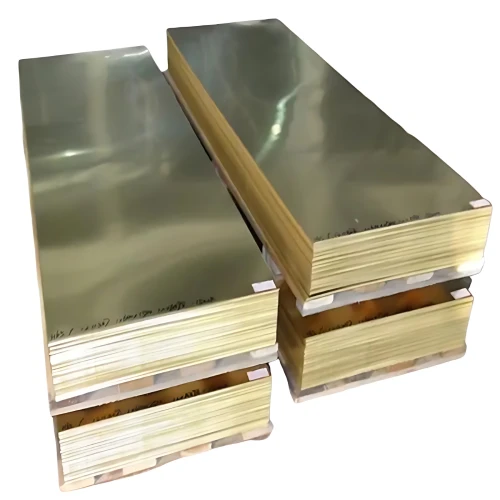

C72500: Copper-Nickel-Tin Alloy for Strength, Corrosion Resistance, and Solderability

C72500 is a copper alloy belonging to the copper-nickel-tin family. It's known for its good combination

of moderate strength, excellent corrosion resistance, and outstanding solderability. Here's a breakdown

of its key aspects:

Table: Key Properties of C72500

| Property |

Description |

| Chemical Composition |

- Primarily Copper (Cu): Minimum 88.2% <br> - Nickel (Ni): Up to 10% <br> - Tin

(Sn): 1.5-2.5% <br> - Other (Fe, Pb, etc.): Trace amounts (Lead-free)

|

| Mechanical Properties |

- Moderate tensile and yield strength <br> - Excellent corrosion resistance, particularly

in marine environments <br> - Excellent solderability due to tin content <br> - Fair

machinability

|

| Common Brands (By Country) |

- Europe: CuNi9Sn2 [Europe] <br> - US: C72500 |

Important Note: C72500 is typically lead-free. However, it's always recommended to

consult the specific datasheet for the material you're considering.

Common Questions and Answers:

What are the typical applications of C72500?

C72500 finds use in various industries due to its well-suited properties:

Electronic components: Due to its solderability and corrosion resistance, C72500 is used

for electronic components and lead frames.

Marine applications: C72500 excels in saltwater environments due to its exceptional

corrosion resistance. It's used for valves, fittings, heat exchangers, and other marine hardware.

Building and construction: C72500 can be used for roofing materials and architectural

elements due to its corrosion resistance and solderability.

How does C72500 compare to other copper alloys?

C72500 offers some advantages:

Excellent corrosion resistance: Especially in saltwater environments, C72500 is superior to

many other copper alloys.

Outstanding solderability: The presence of tin makes C72500 ideal for applications

requiring strong soldered joints.

Lead-free: C72500 is environmentally friendly and avoids health hazards associated with

lead during processing.

However, there are also some limitations:

Moderate strength: Compared to some other copper alloys, C72500 offers moderate strength.

Fair machinability: Machinability of C72500 is not exceptional.

Are there alternatives to C72500?

Depending on the specific application requirements, some alternative copper alloys can be considered:

High-strength copper alloys (e.g., C72900): Offer higher strength but might have slightly

lower corrosion resistance and solderability.

Nickel-aluminum bronzes: Excellent corrosion resistance and good strength, but might be

more expensive than C72500.

Important Note: Always consult with a material engineer or supplier to identify the most

suitable copper alloy for your specific application considering factors like strength, corrosion resistance,

solderability, machinability, lead content (regulations), and cost.