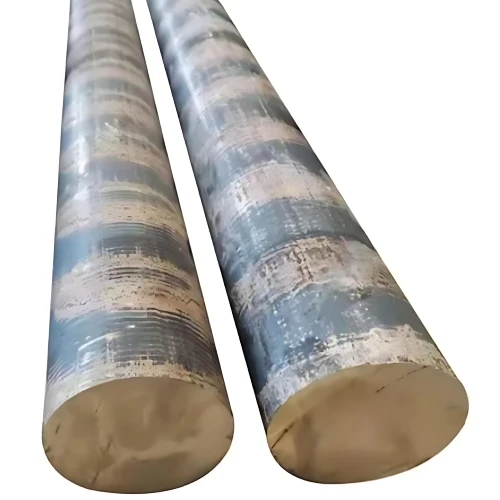

C92300 is a copper alloy belonging to the leaded tin bronze family. It's known for its good combination

of strength, wear resistance, and machinability, making it suitable for various industrial applications,

particularly gears and bushings. However, similar to other leaded alloys, its use is becoming less common

due to environmental and health concerns.

Table: Key Properties of C92300

| Property |

Description |

| Chemical Composition |

- Primarily Copper (Cu): 85.00-89.00% <br> - Tin (Sn): 4.5-6.0% <br> - Lead (Pb):

0.30-1.00% <br> - Other (Fe, Zn, etc.): Trace amounts

|

| Mechanical Properties |

- Good tensile and yield strength <br> - Good wear resistance <br> - Excellent

machinability due to lead content <br> - Fair corrosion resistance

|

| Common Brands (By Country) |

- Europe: CuSn4Pb1 [Europe] <br> - US: Leaded Tin Bronze |

Common Questions and Answers:

What are the main applications of C92300?

C92300 finds use in various industries due to its balanced properties:

Gears: Its strength and wear resistance make it suitable for gears, especially for

lower-load applications.

Bearings and bushings: C92300 can be used for bearings and bushings in applications with

moderate loads.

Wear plates and liners: Industrial machinery can benefit from C92300's wear resistance

for wear plates and liners.

What are the limitations of using C92300?

The main limitations of C92300 are:

Lead content: Lead is a health hazard during machining and limits applications in some

industries due to environmental regulations.

Fair corrosion resistance: C92300 is not ideal for environments with high corrosion

potential.

Are there lead-free alternatives to C92300?

Lead-free alternatives can be considered depending on the specific application requirements. Here are some

options:

C93700: A high-tin bronze with good machinability and wear resistance for bearings and

bushings, but no lead.

Aluminum bronzes (e.g., C95400): Offer good strength, wear resistance, and machinability

without lead.

Important Note: Regulations on lead usage can influence the availability of C92300. Lead

content should also be a factor when choosing a material. Always consult with a material engineer or

supplier to identify the most suitable copper alloy for your specific application considering factors like

strength, wear resistance, corrosion resistance, and regulatory compliance.